|

Instrument Panel

|

|

Page

2

|

|

|

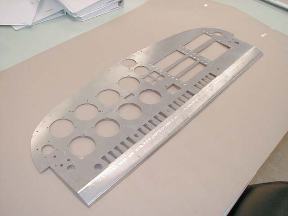

The finished panel fresh

from the waterjet cutter. I found a local Machine shop,

Hollis Line Machine Company,

Inc.

295 South Merrimack Road Hollis,

New Hampshire 03049

Tel. 603-465-2251 Fax. 603-465-2932

Website: Hollisline.com

to cut my panel. I showed

him a full size plot of the file and asked for a quote. The price was

right for me. Depending on the complexity your mileage may vary.

|

|

|

|

|

|

|

I asked John what type of

file format he needed. He said either a DWG or DXF will work. I dropped

off the file and the aluminum later that week.

When I received the panel

back I cut the Aluminum angle for the radio stacks. I even had the waterjet

cut the holes for the flush rivets. I purposely left them small because

of the tolerances of the cutter. I drilled them to the right size when

the panel was finished.

|

|

|

|

|

|

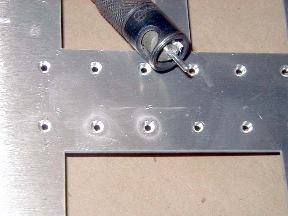

I drilled and cleco'd the

angle to the panel. Flush rivets need to be countersunk. I ran my microstop

countersink through all the rivet holes in the panel. I tried the first

rivet and guess what? the microstop moved from the last time I used it

for the spinner backplate. Lesson learned, Recheck

the countersink on a piece of scrap each time before using it.

|

|

|

|

|

|

This was no big problem. I

filled in the small depression with some super-fil and sanded smooth before

spraying the panel with zinc chromate primer.

|

| |

|

|

|

|

|